EPlus3D

INDUSTRIAL-GRADE 3D PRINTERS THAT CAN KEEP UP WITH YOUR PRODUCTION DEMANDS

GET MORE FROM YOUR 3D-PRINTED PARTS

MASSIVE BUILD VOLUMES AND A VARIETY OF PRINTING MATERIALS TO CHOOSE FROM

IEPlus3D (EP) is a company that focuses on industrial-grade 3D printers that fit perfectly into your production workflow. They offer a range of metal, resin, and plastic 3D printers that are perfect for almost any engineering department.

Their massive metal SLM 3D printers can realistically replace a full machine shop and bring all of your metal fabrication in-house. By adding a metal EP 3D printer to your building, you can save a ton of time and money with each part that you make.

Plus, EP can expedite any prototyping, production, or iterative design phase. You can print a dozen iterations within a single work week thanks to the usability and versatility of each printer on their catalog.

As an industrial-grade solution, EP printers come with a bigger price tag as compared to residential 3D printers. However, the price is more than justified once you look at the precision, repeatability, and functionality of any printer that EP sells. It’s a great option for any engineering department, and they have different sizes and material compatibility for each printer, allowing you to hand-pick the perfect option for your workflow.

EP printers are the best-case option for any engineering department that relies heavily on outside manufacturers. It allows you to have more control over a simplified supply chain, and gives you more power over the final quality of your parts. The machines are easy to install, easy to use, and easy to maintain, so you don’t have to worry about service tasks that slow down your production schedule.

Aside from our expert-level 3D printing services at CAD/CAM Services, purchasing an EP 3D printer is the best way to get parts 3D printed.

EP-M1250 Metal

As one of the largest metal SLM 3D printers on the market, the EP-M1250 metal can completely replace a machine shop. This machine can handle all of your production needs, while creating high-quality, uniform, dimensionally identical parts on a repeated basis.

Printing Technology: Selective laser melting (SLM)

Build Volume: 1250 x 1250 x 1350 mm

Layer Thickness: 0.02mm

EP-M650 Metal

The EP-650 is where EP really distances themselves from their competitors. This massive fabrication center can handle full-scale production runs within a single machine. Expedite your turnarounds and minimize your operational cost with this machine.

Printing Technology: Selective laser melting (SLM)

Build Volume: 650 x 650 x 800 mm

Layer Thickness: 0.02mm

.webp)

.webp)

EP-M450H Metal

The Ep-M450H adds a ton of extra headroom within the build volume, so you can make even taller parts. Alternatively, stack your parts within the 3D printing file to get more units from a single printing operation.

Printing Technology: Selective laser melting (SLM)

Build Volume: 450 x 450 x 1080 mm

Layer Thickness: 0.02mm

EP-M450 Metal

The EP-M450 can transform how your team handles metal fabrication. This standalone unit can start replacing your outsourced fabrication partners, bringing more power and control to your team.

Printing Technology: Selective laser melting (SLM)

Build Volume: 450 x 450 x 550 mm

Layer Thickness: 0.02mm

EP-M400 Metal

Do more with the EP-M400 metal SLM 3D printer. With an impressive build volume and suite of added safety features, this powerful machine can create metal parts in an instant.

Printing Technology: Selective laser melting (SLM)

Build Volume: 400 x 400 x 450 mm

Layer Thickness: 0.02mm

EP-M300 Metal

The EP-M300 falls in the middle of EP’s lineup of metal SLM printers. This 3D printer can make titanium alloy parts that stand up to the demands of your engineering department.

Printing Technology: Selective laser melting (SLM)

Build Volume: 300 x 300 x 450 mm

Layer Thickness: 0.02mm

EP-M260 Metal

For a larger build volume and some added functionality, consider the EP-M260. This metal SLM printer is a great addition to any engineering department that regularly makes metal parts. It can bring some of your manufacturing in-house, expediting each prototype you make.

Printing Technology: Selective laser melting (SLM)

Build Volume: 260 x 260 x 390 mm

Layer Thickness: 0.02mm

EP-M150Pro Metal

The EP-M150Pro is a taller, faster, stronger version of EP’s entry-level M150. This printer in particular will keep up with your metal fabrication demands, assuming your parts can fit within the build chamber.

Printing Technology: Selective laser melting (SLM)

Build Volume: Ø150 x 225 mm

Build Accuracy: ± 0.04 mm

Layer Thickness: 0.02mm

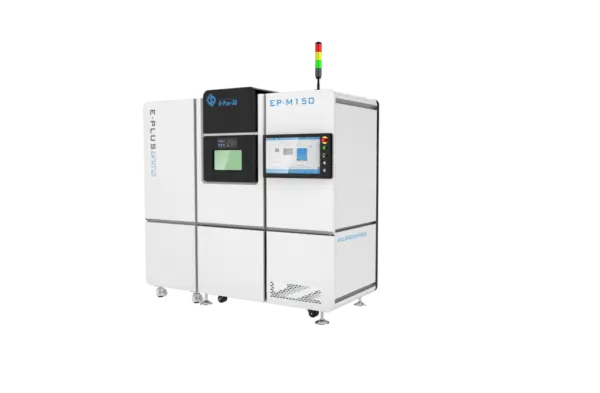

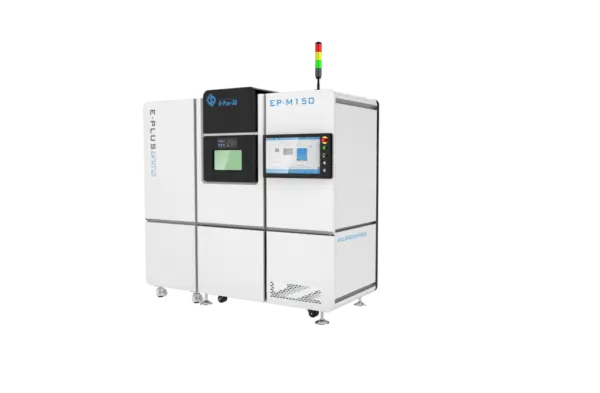

EP-M150 Metal

This 3D printer is EP’s entry-level option for metal 3D printing. This smaller printer has a ton of functionality and versatility, allowing you to make decently sized parts out of almost 100% pure metal alloys.

Printing Technology: Selective laser melting (SLM)

Build Volume: Ø150 mm x 140 mm

Build Accuracy: ± 0.04mm

Layer Thickness: 0.02mm