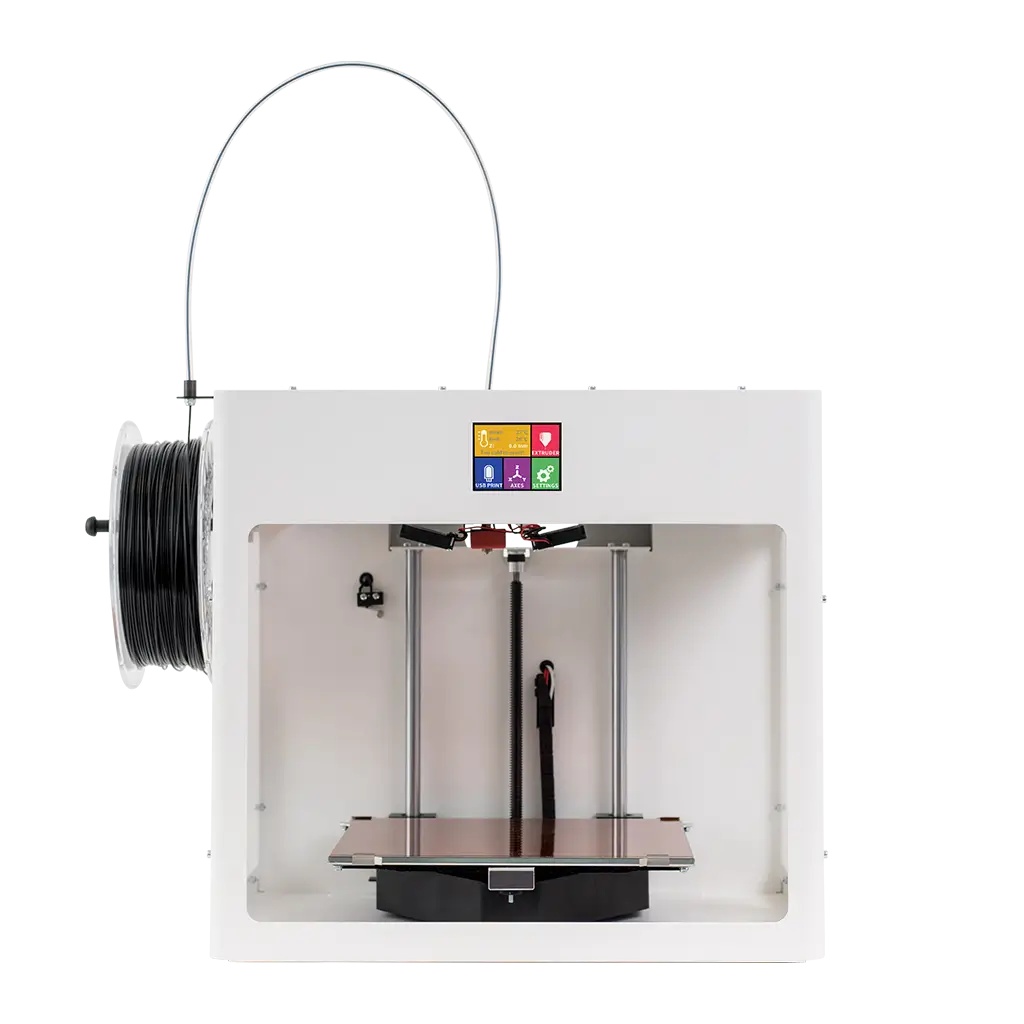

CraftBot Plus Pro

The CraftBot Plus Pro is the most affordable FDM printer currently sold by CraftBot, making it a great option for entry-level 3D printing departments. Although this printer is the older iteration (which has largely been replaced by the “Flow” family), it has plenty of usability and added features.

It has the smallest build volume, but it has a generous temperature range on the hotend, allowing you to print a wide range of materials. Its build accuracy and layer thickness are both impressive, which makes this machine great for handling small and precise parts.

This is a desktop unit, so you can put it on any relatively flat surface and start getting high-quality prints within minutes. The setup is incredibly simple, and it can fit almost anywhere thanks to its small overall size.

Who is the CraftBot Plus Pro for? Engineering departments who don’t know how much 3D printing they’ll do. It might not make sense to spend thousands upon thousands of dollars — yet. With the CraftBot Plus Pro, you can introduce your engineering team to 3D printing and see how advantageous this manufacturing style is for you.

At the same time, this FDM 3D printer is a great option for learning more about the technology. We’ve sold this printer to engineering teams in the past as a means of learning more about how to optimize their 3D printing workflow. After some time, those teams would come back to us and purchase even bigger, more powerful, more expensive FDM 3D printers.

If you want to start making 3D-printed plastic parts and you’re not sure where to start, the CraftBot Plus Pro is a great option.

.jpg)